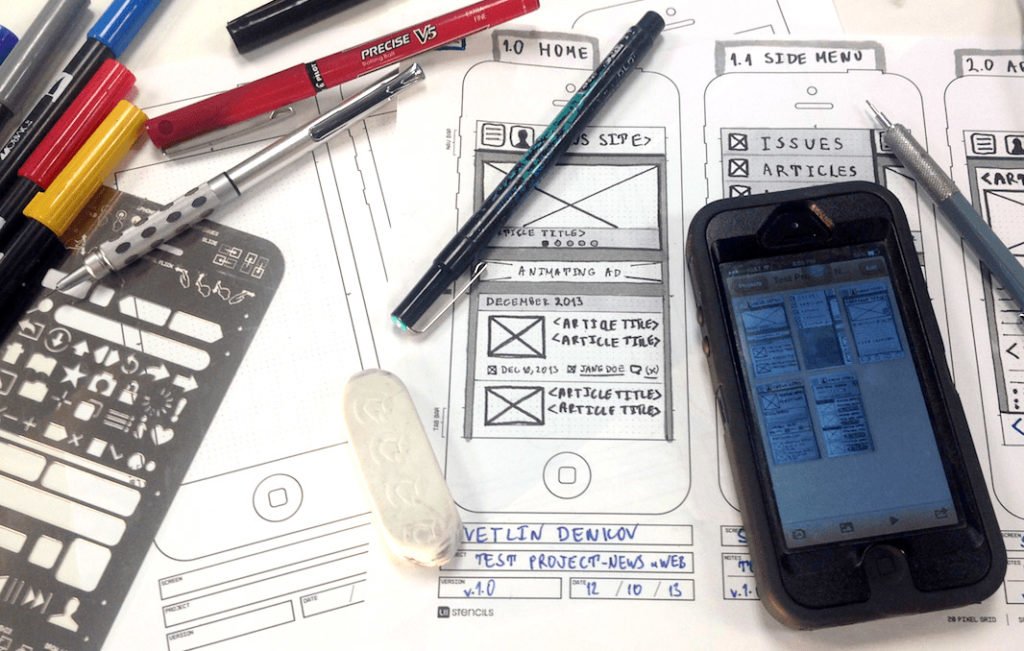

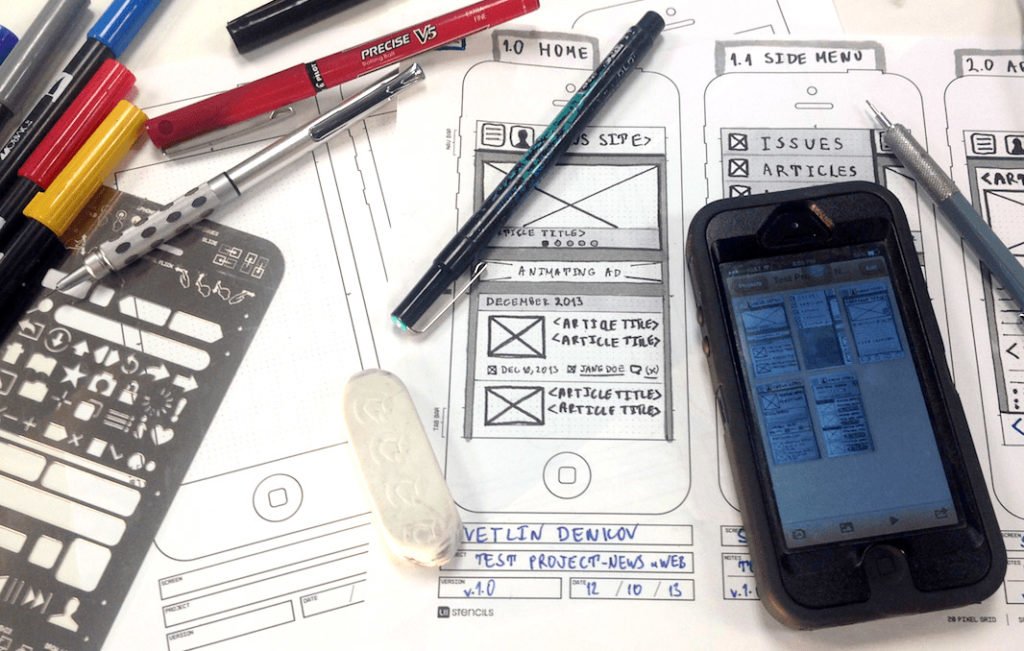

When it comes to developing a product, designing and prototyping really do live side by side, working together to end up with a perfect final product.

What is prototyping?

Prototyping is the step in product design where the design starts to go from just being a concept to becoming a reality.

Usually a physical model will be created, which will then be tested to make sure it is fit for purpose.If not, the prototype will be improved and retested until the designer is content and the product is functional.

It usually takes place fairly early on the process but prototypes can continue to be created right up until manufacturing, as designers test and retest their concepts.

We spoke to Cambridge Design Technology who said: “It’s difficult to overstate just how crucial prototyping is to the design process.

“It allows the designer to prove not only to themselves, but to their investors, that their product is a viable one, and it also allows them to highlight problems that they may never have considered previously.”

Reasons prototyping might be used

- Sometimes it can be hard to visualise what a finished product is going to look like, and things can get bogged down in theories and concepts. In this case, a concept prototype is made to give a tangible idea of the final product.

- Sometimes a prototype is required to present to investors or superiors within a company and in these cases a simple display prototype is used. These will usually look extremely similar to how the final product will, but might not actually fully work the same.

- If the final product will need to show certain properties such as a resistance to heat, a prototype might be mocked up which will mimic these properties so that it can be tested.

- Prototypes might also be produced using the manufacturing process that will be used for the final product to prove that the product can be viably manufactured.

Types of prototyping tech

Nowadays there’s a wide range of technology being used in product prototyping, using many different materials to replicate the properties which need to be present in the final product.

The most popular at the moment is 3D printing (also known as rapid prototyping), but did you know there are numerous different types of 3D printing?

- Stereolithography (SLA) is probably the most common method of 3D printing, using a laser to cure the printed material. It’s one of the quickest methods available and allows some parts to be printed within a 24-hour period.

- Selective laser sintering is also common, and involved ‘sintering’ powder layer by layer to create the final product. It’s most commonly used in instances where low numbers of a product are necessary.

- Fused deposition modelling is a lower cost method which is often used for early stage prototype parts.

- PolyJet is another method which creates very smooth, accurate parts and is usually only used for very complex products and parts.

Check out this article from Search Manufacturing ERP for more information on rapid prototyping.